Hey thanks for the interest and encouragement guys.

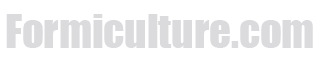

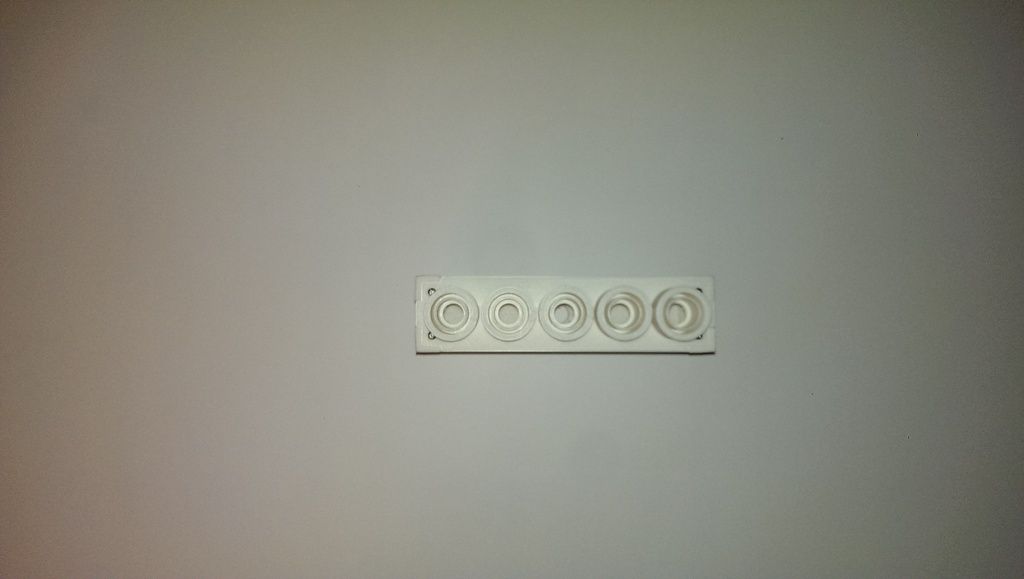

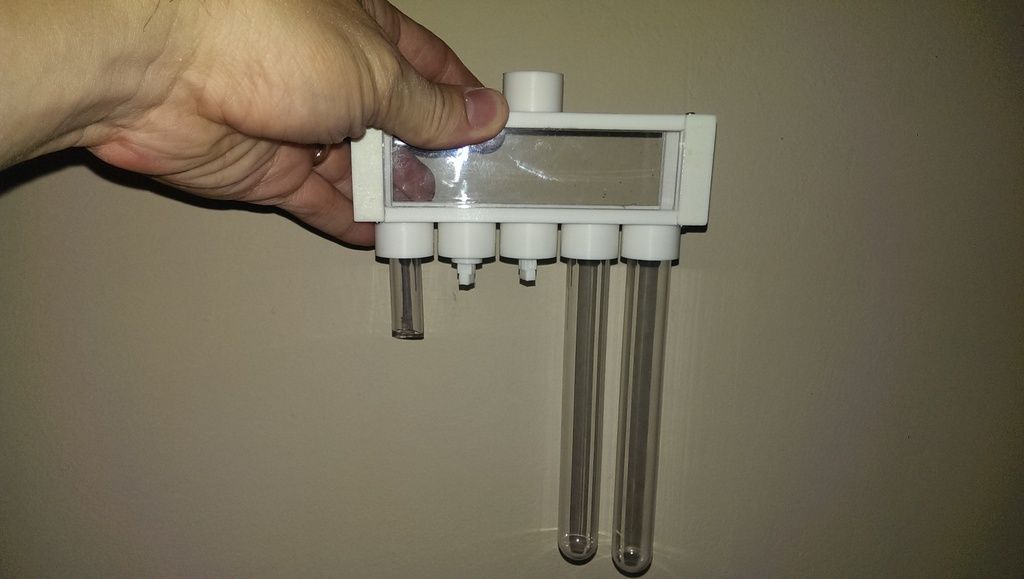

I ended up going with some of your suggestions. Now the ports to the chamber can fit 1 of 3 things: a test tube, .5OD vinyl tubing, or a 3d printed plug. I replaced the dowels with threaded inserts and screws, so no more breakage. I changed some of the the measurements, so now everything fits more snug than before. However, because of the minor deviations in test tubes, I could only get about 85% of the test tubes to fit tightly, with about 75% fits tightly enough to flip it upside down without falling out. Here is a video demonstrating the how snug and what kind of force is required to install and remove the test tubes, tubing, and plugs. Sorry the shakiness, I am a one man show without a camera stand.

The only thing left for me to do is to widen the slots where the plexiglass fits and widen the screw holes a little bit. It is entirely too tight and slightly difficult to put together.

I plan to have another prototype Sunday night. I think functionality wise, this project is finished. Once I fix the slots, I will post again the market place.

These are my ideas for future projects:

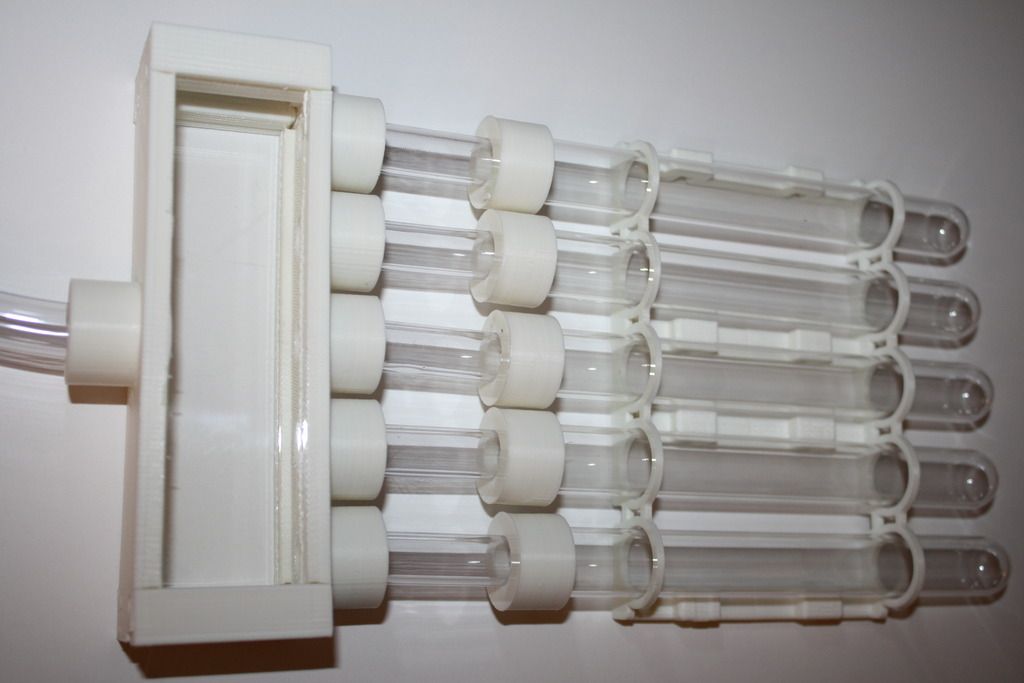

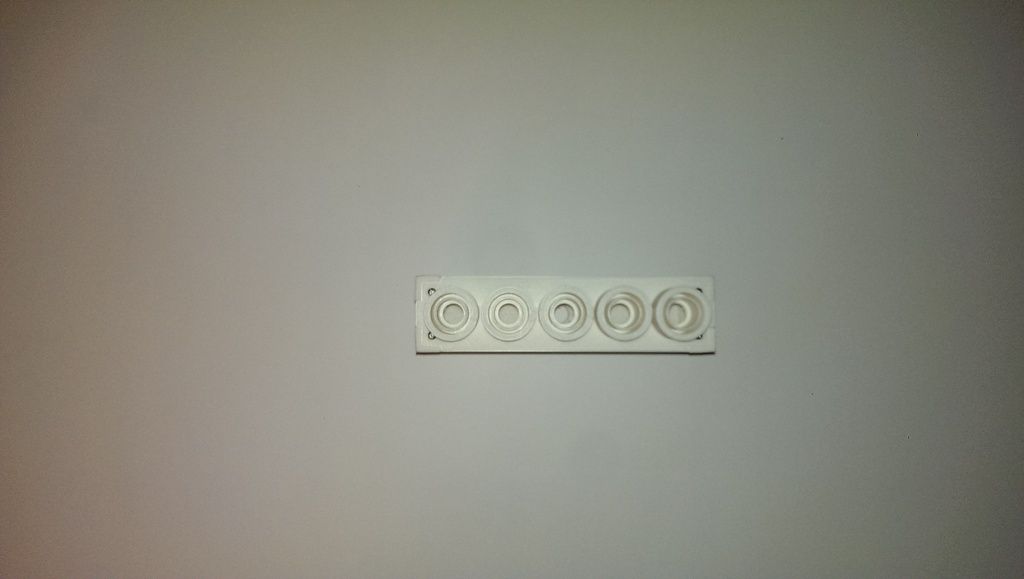

1. The port with options, but more like a single ring connection like I posted previously. It sounds simple with my current measurements, but the printing material warps on one side, throwing off the measurements entirely.

2. A 2,3,4 way connection for the vinyl tubing, test tubes, and plugs.

3. A cleaner connection to the tubing and out world.

![]()